M2

The M2 universal mixer is designed around the time proven STS Sam-Series Mixers. The M2 mixer is available with 4 different power options that drive a 2” centrifugal pump, making effective use of the proprietary 4 point mixing system. The M2 can be used as a new installation or retro fitted into an existing tank. Since the unit is connected by hoses and not hard pipes, the placement of the mixer to the tank is less restricted and a configuration to suit the needs of the contractor and available space, are easier to achieve. The small size also makes it a portable, independent unit that is easier to transport from site to site. The M2 pairs up well with the StS UTK-500 (500 us gal.) mixing tank with internal educator nozzles.

M3

The M3 universal mixer is designed around the time proven STS Sam-Series Mixers. The M3 mixer is available with 4 different power options that drive a 3” centrifugal pump, making effective use of the proprietary 4 point mixing system. The M3 can be used as a new installation or retro fitted into an existing tank. Since the unit is connected by hoses and not hard pipes, the placement of the mixer to the tank is less restricted and a configuration to suit the needs of the contractor and available space, are easier to achieve. The small size also makes it a portable, independent unit that is easier to transport from site to site.

M4

The M4 universal mixer is designed around the time proven STS Sam-Series Mixers. The M4 mixer is available with 4 different power options that drive a 4” centrifugal pump, making effective use of the proprietary 4 point mixing system. The M4 can be used as a new installation or retro fitted into an existing tank. Since the unit is connected by hoses and not hard pipes, the placement of the mixer to the tank is less restricted and a configuration to suit the needs of the contractor and available space, are easier to achieve. The small size also makes it a portable, independent unit that is easier to transport from site to site.

M-375

The M-375 was the original Sam-Series Mixer, designed and manufactured primarily for use with mini size drill rigs as an alternative to using plain water. The M-375 is available with 4 different power options that drive a 3” centrifugal pump, making effective use of the proprietary 4 point mixing system. This Bentonite mud mixer is capable of providing 375 gallons of full yield mud to your drill rig in less than 5 minutes. The compact unit can be transported to the job site in a standard 8’ pickup box.

M-500

The M-500 is designed and manufactured primarily for the HDD mini size drill rigs and tunnelers, as an alternative to using plain water. Powered by a 10 hp air-cooled gasoline engine, driving a 3” centrifugal pump that makes effective use of the proprietary 4 point mixing system, making it fast and powerful. This Bentonite mud mixer is capable of providing 500 gallons of full yield mud to your drill rig in less time than the competition. This unit can be mounted in a truck or on a trailer and transported to the job site with ease.

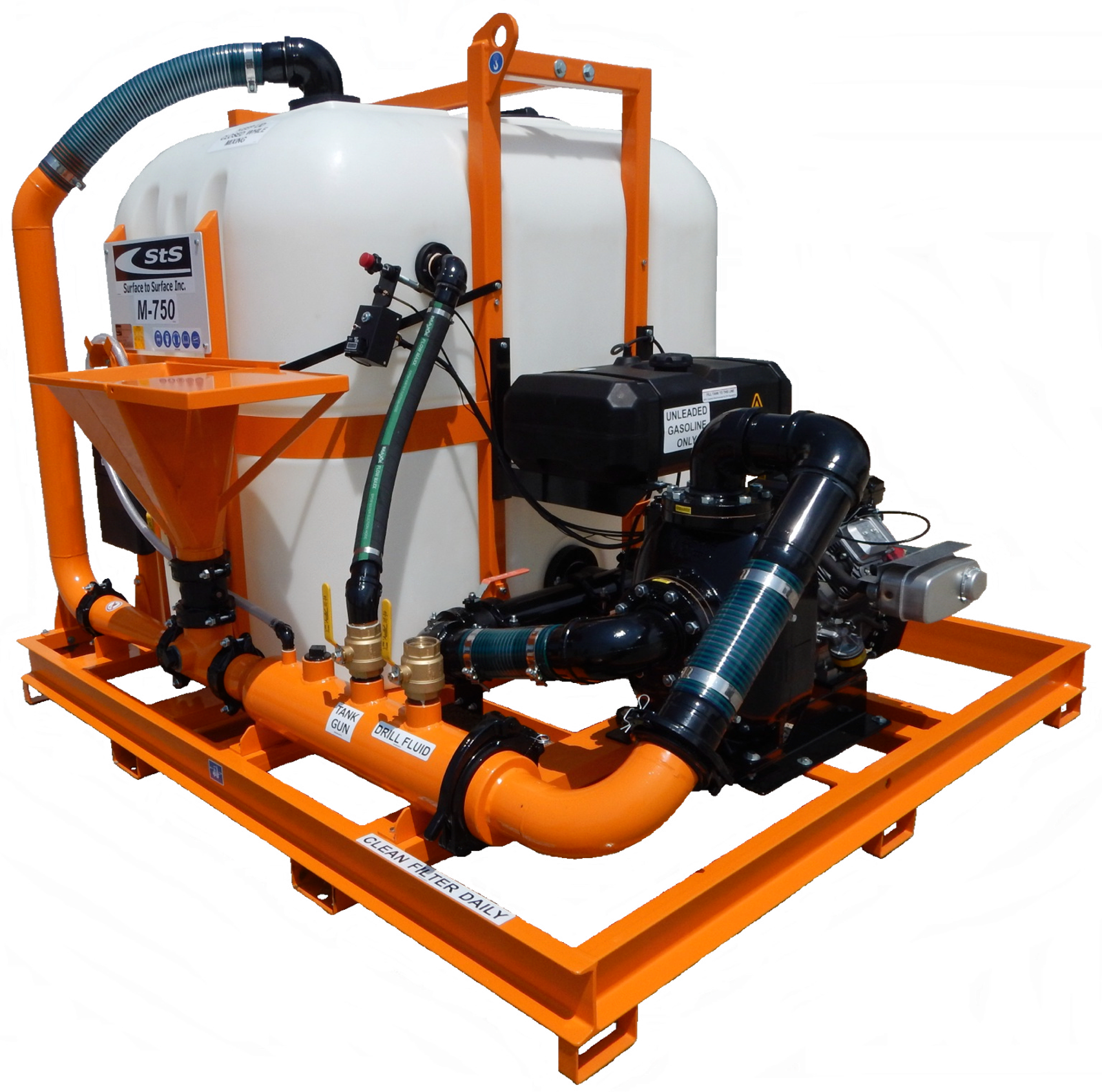

M-750

The M-750 with its rectangular loaf shaped Roto-Mold tank is a space saving design with an almost square footprint dimensions. The M-750 is available with 4 different power options that drive a 4” centrifugal pump, making effective use of the proprietary 4 point mixing system. The M-750 Bentonite Mud Mixer is capable of providing 750 gallons of full yield mud to your drill rig in less than eight (8) minutes. Added benefits to this unit include the ability to draw water from a second tank and send mud to your drilling rig or storage tank without the use of a second pump.

M-1500

The M-1500 was designed and manufactured as a dual tank system that allows the HDD Contractor two methods of mixing there Bentonite mud requirements. This system allows the operator to mix 750 gallons of full yield mud in less than eight (8) minutes, while holding 750 gallons of water reserve in the second tank for the next mix, or mix 1500 gallons of full yield mud in less than sixteen (16) minutes, in one large batch. The operator controls the two methods of mixing by changing the direction of flows through the piping connections using the manual operated full flow valves. The vacuum port located in the mixing tee has the ability to draw water from the second tank when being used as a reservoir and the drill fluid can then be sent to the drilling rig with-out the use of a second pump. This model has been a popular choice of HDD Contractors due to its small space saving footprint relative to its capacity.

PR-10-S PIPE ROLLERS

The PR-10-S was developed for the contractor who uses smaller diameter pipe sizes and varying job conditions. The large flat bottom base makes the unit very stable when used on uneven ground. The low profile allows the roller to be used on the ground or raised up on cribbing to a desired ground clearance. The unit does not need to be reconfigured or adjusted (1 roller, 2 bearings) to handle different sizes of pipe from 0 to 10 inches. These small units can be carried by one person or by simply turning over onto the roller and rolled to the next spot. The units can be stacked atop each other for space saving storage. These rollers are very rugged and versatile and can be used for many different applications on the job.

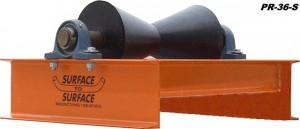

PR-36-S PIPE ROLLER

The PR-36-S was developed for the contractor who uses a wide range of pipe sizes and varying job conditions. The large flat bottom base makes the unit very stable when used with large diameter pipe ranging from 0 to 36 inches. The low profile allows the roller to be used on the ground or raised up on cribbing to a desired ground clearance. The unit does not need to be reconfigured or adjusted (1 roller, 2 bearings) to handle different sizes of pipe. The units can be relocated on the site by simply turning over onto the roller and rolled to the next spot. The units can be stacked atop each other for space saving storage. These rollers are very rugged and versatile and can be used for many different applications on the job.

M-300/M-400

Transfer Pump

The M-300/M-400 series transfer pumps were designed for the contractor who required a separate holding tank were they could keep the drill fluid mixing and at the same time transfer to the drill rig. These units are available in 4 different power units and either a 3” or 4” centrifugal pump.